Physical Models for Core Losses

The conversion of electrical energy becomes more and more important due to the necessity of reducing greenhouse gas emissions. This means that new power electronic converters must be at the same time energy-efficient, cost-effective, and material-saving. This requires optimising the converter components such as the magnetic components (inductors or transformers). To decrease the time-to-market, the optimisation is typically done based on virtual prototypes, which are sets of mathematical models representing the quantities of interest of the component such as its operating temperature or its losses.

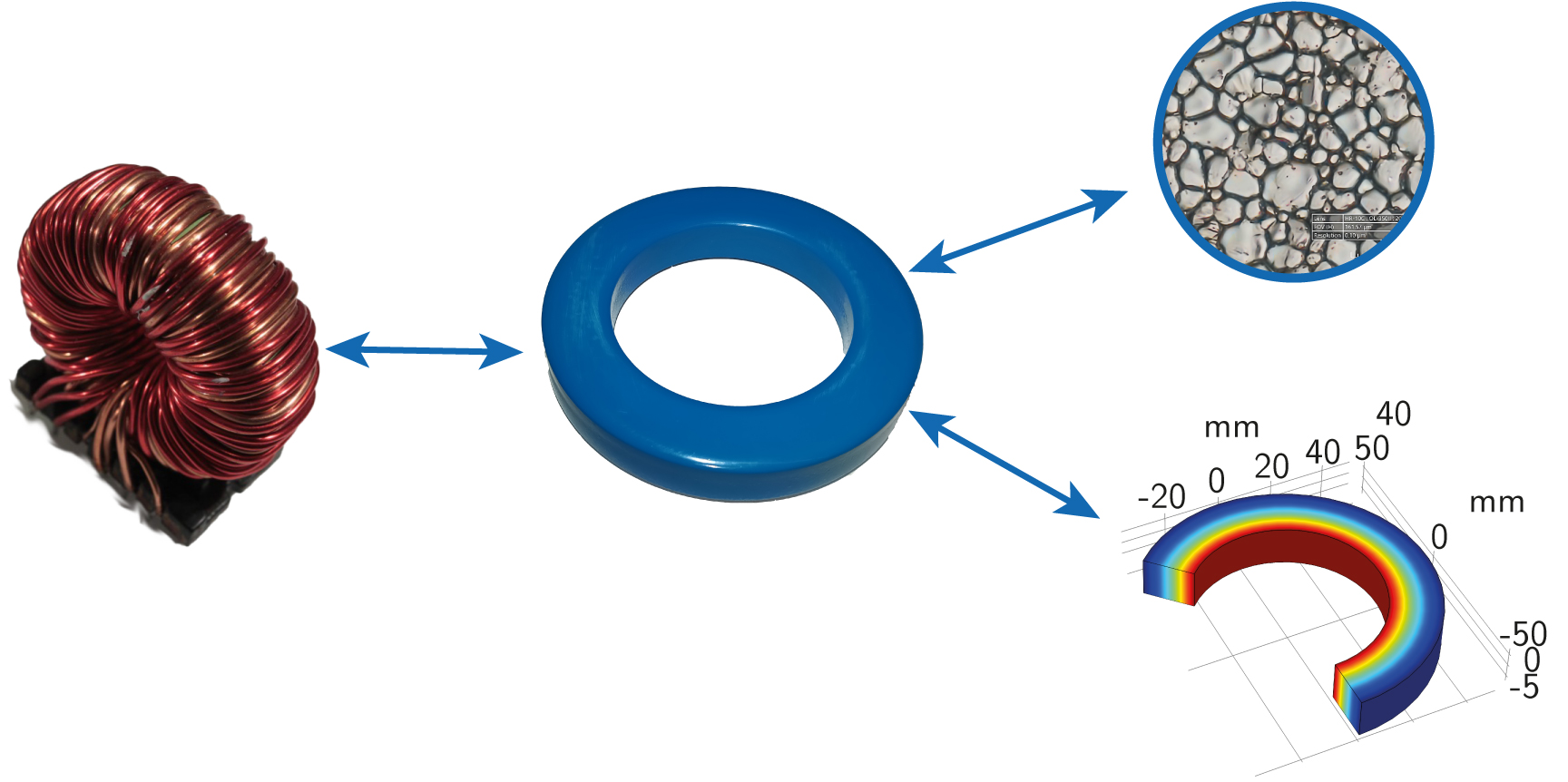

In the case of magnetic devices, one of the major sources of losses is the ferromagnetic core, often made of ferrite in power electronics. With the increasing operating frequencies enabled by new wide-band-gap semiconductors (above 100kHz), modelling the core losses using traditional empirical methods has proven to be unreliable.

To get accurate estimations of core losses, a project was launched at HPE with the goal of developing a new approach based on physics. The new methodology is built upon three pillars: The analytical solution of the magnetic field in the core including resonances, the modelling of the material non-linearities, and the development of core loss calculation algorithms combining the field calculation and the material model.

Ferrites exhibit a high permeability but also a very high permittivity (also known as dielectric constant). This means that at high frequency, an electromagnetic resonance can occur in the core, leading to a change in the field distribution in the core and to additional losses due to the induced resonant eddy currents. In the project, the state-of-the-art is expanded by developing methods to account for the resonance in core shapes that had not been covered before.

To run magnetic field calculations, one needs the electromagnetic properties of the core (permeability, permittivity, and conductivity). However, ferrites are very complex materials. They are sintered metal-oxide ceramics, meaning that they feature non-linear electric conduction and a meta-material behaviour (the properties are vastly different at micro- and macroscopic levels). In the project, a new comprehensive material model of ferrites is developed based on physical first principles.

The field solution is derived assuming ideal material parameters. But ferrite are a non-linear material, which is incompatible with the field solution. To enable the calculation of core losses, a new procedure is developed which links the model of the field and the model of the material. This procedure proves itself be not only accurate but also very fast.

Through an innovative methodology, the project has enabled the calculation of core losses using a new physical approach. This not only opens new prospects for the development of high-frequency power electronic converters, but also to the development of new ferrite materials by using physical parameters to the model. Using physical parameters enables the translation of the power electronic problem of core losses into the language of material engineering.