Highly Integrated Modular Drive Inverter Concepts

In a first part of the project, an integrated drive inverter is developed for a given motor which is a 1.5 kW permanent magnet synchronous machine for high-torque, low-speed applications.

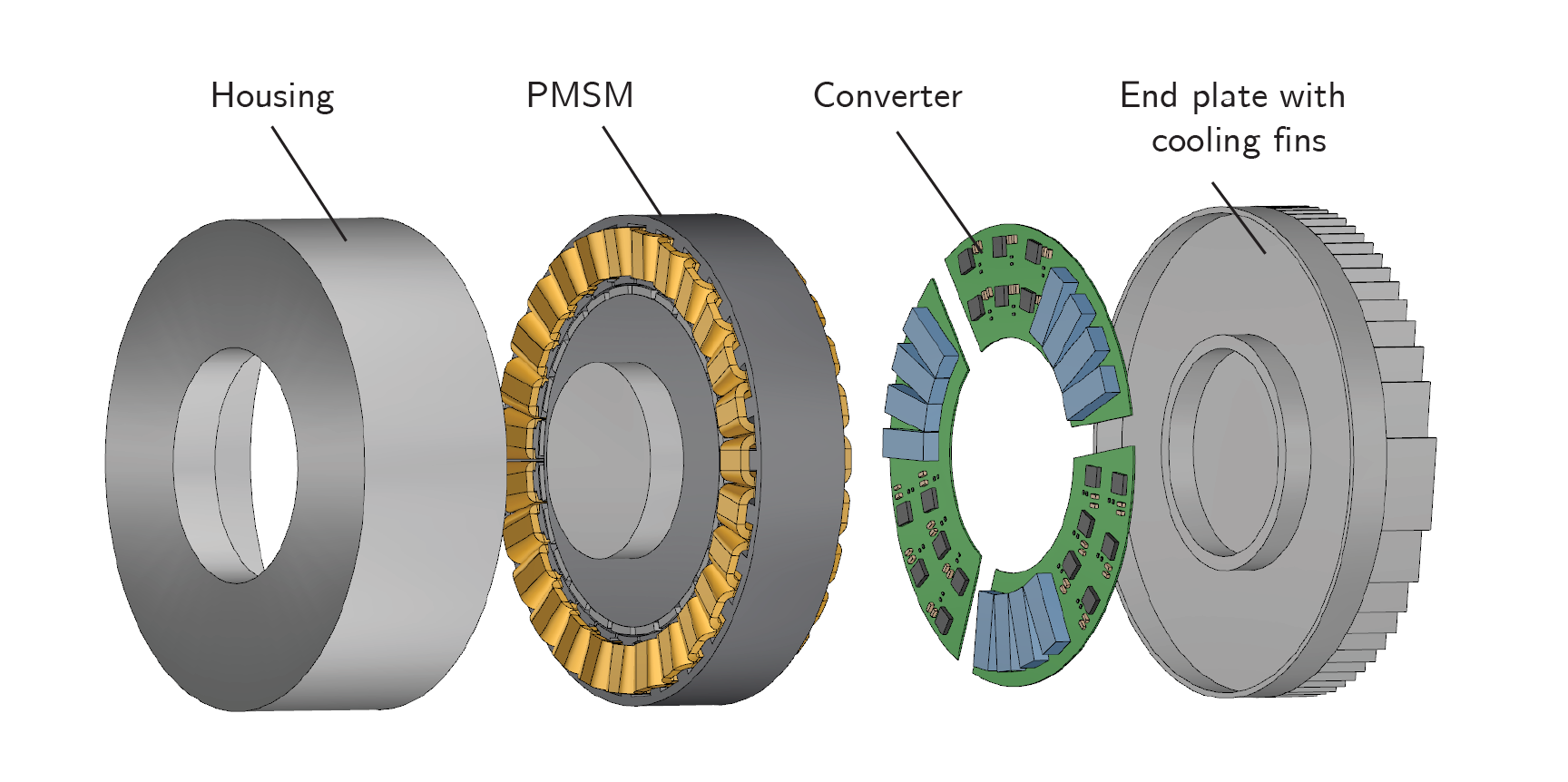

Therefore, first, a thermo-mechanical integration concept is developed that allows for a high degree of integration and for an efficient cooling of both the motor and the inverter. Different integration concepts are evaluated with regard to available inverter space and cooling performance, also taking existing concepts from literature into account. The evaluation results in axial integration with a thermal insulation layer between the motor end windings and the inverter to be the most suitable integration concept for the considered motor.

In a next step, different inverter topologies and PWM schemes are compared. In addition to conventional 2-level and 3-level topologies, a focus lies on modular topologies that also require a modular motor winding. Potential advantages of modular topologies are an increase in fault-tolerance/redundancy, a reduction in cost through economies of scale, a reduction in semiconductor losses, and the possibility to use multiphase motor windings. Multiphase motor windings have more than three magnetic axes which leads to higher torque-densities through higher winding factors using tooth-coil windings.

A preselection of the most promising system configurations in terms of the integration concept, the inverter topology, the PWM scheme, and the semiconductor device technology (SiC/GaN) is electrically and thermally modelled. The models are then used in a multi-objective optimization routine to determine the optimal design parameters for maximum efficiency/power density and minimal cost. The optimal results should be validated in a prototype.

In a second part of the project, the motor is considered variable and is included in the design procedure. Therefore, a scalable motor model and a design routine for the optimal design of the complete electrical drive system (inverter + motor) should be developed.